Prusa i3 MK2

Last year I purchased the new kit version of the original Prusa i3 MK2. It finally arrived and it was worth the waiting. I ordered the third printer only because I want to try building a printer. Both printers I already own are already assembled ones. So I said to me the Prusa has a bigger build volume and an interesting bed levelling function, this is a good reason to buy one 😊

Here are some technical specifications for the kit version I purchased:

- Build volume 25 x 21 x 20 cm

- 0,4mm nozzle

- 1,75mm filament diameter

- E3D V6 Full hot end

- PEI print surface & heat bed

- Automatic mesh bed levelling (9 points)

- Integrated control board which prints from SD card

Build

Here are some pictures during the build. The build was so relaxing that I totally forget to do more pictures. Initially there was a time-lapse planned for the build, but there are already some on YouTube, so I didn’t make it.

For the build I didn’t use the printed version of the manual. I used the online version because of the high resolution pictures included. I only had two small issues during the build.

Number one was the motor mount and belt holder on the Y-axis had not big enough holes to slide on the threaded rods. I screwed the threaded rods into the parts what gave me a headache after the assembly, when I tried to correct the position of these parts. Here I totally had to drill the holes wider first so that the parts can slide on the threaded rods.

Number two was the extruder assembly. To get this part together without M3 nuts falling out on each side was a little bit tricky … to put it charitably 😉

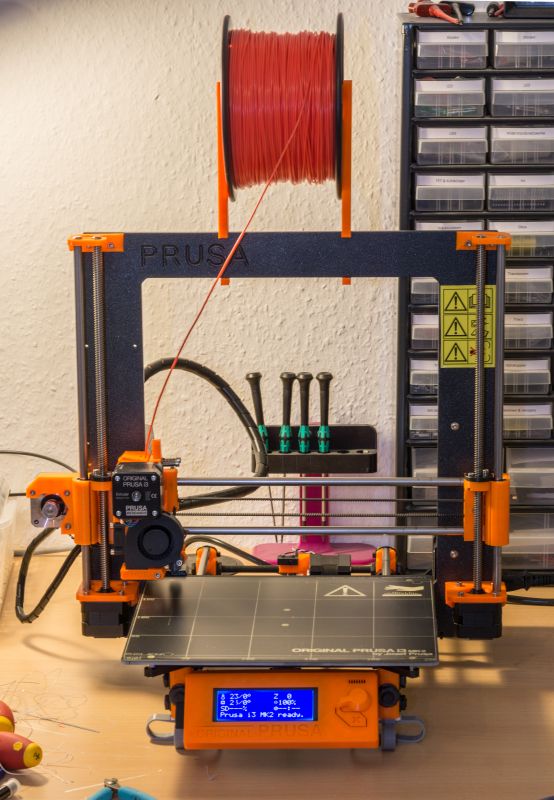

And here is the final printer on its current position:

Prints

I already printed some parts on the new printer and the overall quality of the prints is simply awesome. But see for yourself:

This is the 3DBenchy (Thingiverse link) which I tested with silver PLA and a layer height of 200µm.

This is a dual-color print which was on the SD card already. Here the print stopped after the silver part was printed. Then you can load new filament into the printer and extrude as much as you need to get the old color out. After the new color extrudes correctly you can resume the print with one click on the control board. This is a nice feature which I want to test more in the future.

Here is a stepper motor holder which I designed in Autodesk Fusion 360. I scaled the part to 102% and the stepper motor slides in smoothly. Also, the print quality is amazing.

This is the hairy lion (Thingiverse link) in silver PLA. Click on the image for a higher resolution. It came out beautifully.

Conclusion

So, I love the new Prusa i3 mk2 and I will print many things which doesn’t fit on the print bed of my Lulzbot Mini. But the Lulzbot Mini will be used also. Both machines are nice for starting a print and coming back later for the finished part. I can now use my box full of 1,75mm PLA from my first printer with the Prusa and print my 3mm HIPS with the Lulzbot. So no longer unused filament lying in the basement.